I 16

I Safety

Safety data on production units

Heineken Group*

Our strategy

In order to meet our objectives, all production

units are required to set local targets for accident

frequency and severity as part of their Operational

Plan. These targets should be in line with the overall

objectives of Heineken. The safety parameters

are monitored and benchmarked on a quarterly

basis through our Brewery Comparison System.

Furthermore, safety has been integrated into our

TPM Programme.

The Heineken Company has standards for the

design of brewery equipment to ensure safe

installations. Knowledge and best practices

are collected and communicated in order to

continuously improve the safety of our installations.

Our production units perform maintenance of

their installations and have operating procedures

in place to help ensure that nuisance (for instance

noise and odour emissions) is reduced.

We make efforts to minimise the nuisance to our

neighbouring communities and take action on

recorded complaints. We do our utmost to comply

with legal requirements. Nevertheless, occasionally

fines are levied due to non-compliance.

Activities in 2007

In 2007, we implemented the safety pillar of our

TPM programme in a number of our breweries.

This programme offers an instrument to reduce

the number of accidents, ultimately aiming at zero

accidents. A workshop was conducted for all our

Western European Operating Companies. As a

result of this workshop, specific activities which

support the TPM safety pillar and which build on

the initiatives already in place were started in

several breweries including 's-Hertogenbosch

(Netherlands), Marseille (France), Valencia and

Madrid (Spain).

There were continuous training sessions with

regard to safety across our business, in some

cases in combination with awareness programmes

for employees; for example, in Nigeria a national

Safety, Health Environment week was organised.

During the year, we also issued a new standard

specifically designed to address safety and

emergency procedures related to all greenfield

site activities given the increased risks of these

types of projects.

In Mawathagarma (Sri Lanka), a safety and health

committee was established and an awareness

programme was implemented. This programme

included the provision of relevant personal

protective equipment and the enforcement

of its use. An awareness programme was also

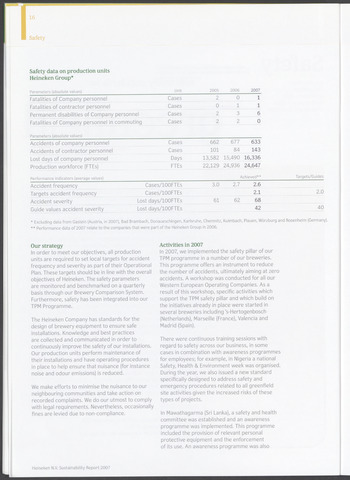

Parameters (absolute values)Un't2005

Fatalities of Company personnel

Cases

2

0

1

Fatalities of contractor personnel

Cases

0

1

1

Permanent disabilities of Company personnel Cases

2

3

6

Fatalities of Company personnel in commuting Cases

2

2

0

Parameters (absolute values)

Accidents of company personnel

Cases

662

677

633

Accidents of contractor personnel

Cases

101

84

143

Lost days of company personnel

Days

13,582

15,490

16,336

Production workforce (FTEs)

FTEs

22,129

24,936

24,647

Performance indicators (average values)

Achieved**

Targets/Guide's

Accident frequency

Cases/lOOFTEs

3.0

2.7

2.6

Targets accident frequency

Cases/lOOFTEs

2.1

2.0

Accident severity

Lost days/100FTEs

61

62

68

Guide values accident severity

Lost days/100FTEs

42

40

Excluding data from Gastein (Austria, in 2007), Bad Brambach, Donaueschingen, Karlsruhe, Chemnitz, Kulmbach, Plauen, Würzburg and Rosenheim (Germany).

Performance data of 2007 relate to the companies that were part of the Heineken Group in 2006.

Heineken N.V. Sustainability Report 2007